YIT Live Bee Cam offers a glimpse of the life in a beehive

- News

- 14.11.2018 09:00 CET

The Finnish National Opera and Ballet set workshop took its schedule under control with insights from a construction site

YIT Corporation News, November 14, 2018 at 10:00 a.m.

YIT has used the Last Planner method at its construction sites since 2010. Now, the same method is used at the Opera and Ballet workshops.

Few people know or even think about the amount of work that has been done behind the scenes of the Finnish National Opera and Ballet before the curtain goes up for the audience.

“The design and implementation of the performance set is generally started a year before the premiere,” explains Janne Säkkinen, Assistant Head of Set Workshop at Finnish National Opera and Ballet.

During that year, the performance set is designed and constructed at the Opera’s and Ballet’s own design agency, wood, properties and metal workshops, upholstery as well as paintshop, that together employ 31 people.

It is Säkkinen’s responsibility to ensure that cooperation between the different departments functions and that their schedule goals are realistic. In an ideal situation, the last link in the chain—the paintshop—does not need to hurry to catch up with the schedule right before the premiere. However, in practice, this used to be a regular occurrence in recent history.

“This is why, in August 2015, we started our own Lean* path and training. At first, as the Lean method prescribes, we focused on the workshop’s equipment management, which means we did a proper cleansing and figured out a sensible location for each item. Simultaneously, we committed to keeping everything in its place,” Säkkinen explains.

Just clearing out the workshop was a big help in managing the production flow. As the basic methods of Lean were now familiar to the employees, it was easy to move on to schedule control.

Higher expectations for the set

The Opera and Ballet set workshop constructs all the set props themselves. There are generally seven premieres each year: four for opera and three for ballet.

In the past years, technical development has led to higher expectations for the set: more extravagance, digitality and three-dimensionality. However, the number of work hours has not increased in the same ratio, which has caused challenges for scheduling.

Initially, Säkkinen and his colleagues started searching for solutions from the Lean Six Sigma and then the Lean Practitioner 2018 Program trainings. In the latter, Säkkinen met Maarit Sääksi, who has led YIT’s Performance Leap programme that started in 2016. The goal of Performance Leap has been to increase YIT’s competitive edge through development, not cuts. Important tools in the work were cooperative project management methods and Lean.

“Soon, we noticed with Maarit that our problems were very similar to problems at construction sites. YIT’s project management had received excellent results with the Last Planner tool. We became interested in the tool and were able to see it in action at the YIT Töölönkatu parking hall site,” Säkkinen explains.

The visit to the construction site in March was so impressive to Säkkinen that he printed the first Last Planner platform on the set workshop wall as soon as he got back to work.

Transparency brought more team spirit

Last Planner (LP) is a technical and social operating model to visually schedule different kinds of projects. YIT has been using LP since 2010. At first, it was used in infrastructure projects and afterwards even elsewhere in the Group.

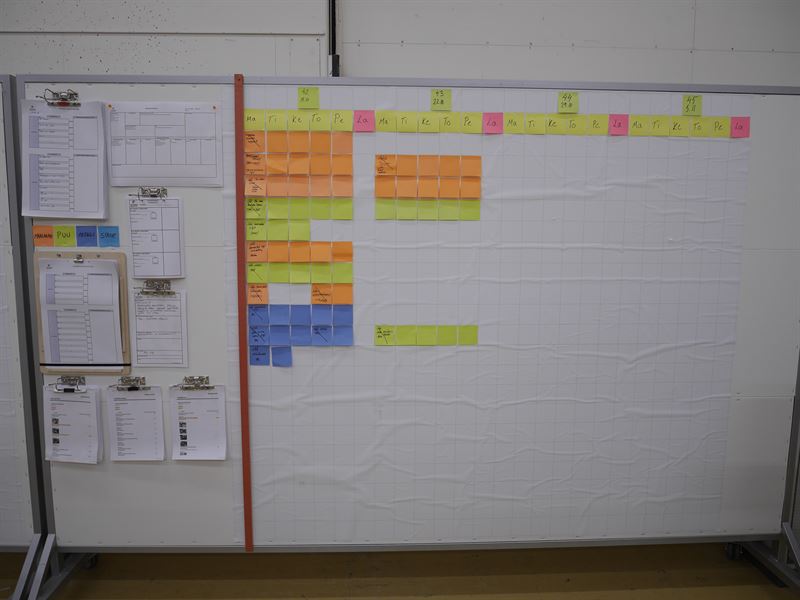

The project phases and necessary tasks are added to a Last Planner timeline on the wall.

The schedule is hung somewhere where the entire project staff can always see it—on the workshop wall. LP illustrates how the project is proceeding and how different employees’ tasks affect how colleagues’ work will proceed, or, in a worst-case scenario, come to a halt.

“We are an art institute, and, at first, our employees were worried about LP taking the creativity and freedom away from their work, that we would become like a Toyota assembly line. The concern was unnecessary. On the contrary, the common goal and clear transparency to each other’s tasks and schedules have made us work together even better, which has improved our team spirit,” Säkkinen describes.

The standardised processes have helped the set design get closer to their goal of a relaxed working pace. Säkkinen has already presented the Last Planner method to other departments at his workplace of 530 employees. The tool has created interest in at least the Opera and Ballet sound department.

Never finished, but there is always room for improvement

The set design’s Lean path will continue by developing the use of Last Planner in the upcoming months and years. The aim is to finetune the operating method to suit set design in particular. Insights are also shared with other national and international art institutions, as Opera regularly exchanges schedule management know-how with YLE’s set design, Helsinki City Theatre and National Theatre as well as through the international Opera Europa forum.

According to Säkkinen, the best thing about implementing Last Planner and Lean has been that now, if a problem needs to be solved, the focus is on improving the process, not looking for the guilty parties.

“We have created a problem-solving team where the members change every three months. When there is a problem in the process, they are handled by the team, which comes up with ways to improve the process so that things would go better in the future,” Säkkinen illustrates.

Säkkinen says that before, he thought that the set design would be “leanified” by XXXX. Instead, he has now understood that instead of reaching a goal, it is all about continuous improvement.

*The term Lean comes from the Lean Manufacturing model that car and electronics manufacturer Toyota made famous. It is about principles that help you reach quality, speed and customer-oriented operations. Lean removes everything that does not add value and work is done only on tasks that must be completed at that specific moment. Lean brings added value to how the team functions as a unit. Lean’s approach is to respect the people who do the work, and these people are also the ones who know how to do the work. A framework must be created for the team to function efficiently and their expertise must be trusted to reach the desired outcome.

Cooperation and interaction are key aspects of modern construction

Performance Leap reduces waste and aims for a faster project turnaround time.

YIT’s Performance Leap development programme has helped reduce waste in current operating practices and processes, thereby improving competitiveness. Cooperation and interaction are key aspects of modern construction, which can be seen in the visual management practices at construction sites. Visuality and cooperation at YIT are now operating methods that are no longer dependent on the contract model. Kick-off events arranged at the start of projects, for example, provide an opportunity to agree on shared targets and ensure that all project parties are committed to them. Production management is enhanced by Last Planner, a scheduling technique that makes workflows more predictable.

In practice, eliminating waste means better production flow and shorter project turnaround times without increased resources. One practical example is an infrastructure project whose turnaround time was reduced from 20 months to 16 months with the help of the Last Planner technique. In a pilot housing project for the Performance Leap programme, the interior building phase of an apartment building was reduced by 50 per cent as a result of pace scheduling. Shorter turnaround times do not mean lower quality. On the contrary, pace scheduling means more real-time quality inspections and immediate detection of possible defects.

Further information:

Hanna Malmivaara, Vice President, Communications, YIT Corporation, tel. +358 (0)40 561 6568, hanna.malmivaara@yit.fi

YIT is the largest Finnish and significant North European construction company. We develop and build apartments, business premises and entire areas. We are also specialised in demanding infrastructure construction and paving. Together with our customers our 10,000 professionals are creating more functional, more attractive and more sustainable cities and environments. We work in 11 countries: Finland, Russia, Scandinavia, the Baltic States, the Czech Republic, Slovakia and Poland. The new YIT was born when over 100-year-old YIT Corporation and Lemminkäinen Corporation merged on February 1, 2018. Our pro forma revenue for 2017 was over EUR 3.8 billion. YIT Corporation's share is listed on Nasdaq Helsinki Oy. www.yitgroup.com